Fasteners and Machining: Key to Efficient and Dependable Production

Fasteners and Machining: Key to Efficient and Dependable Production

Blog Article

Browsing the Globe of Fasteners and Machining: Strategies for Accuracy and Rate

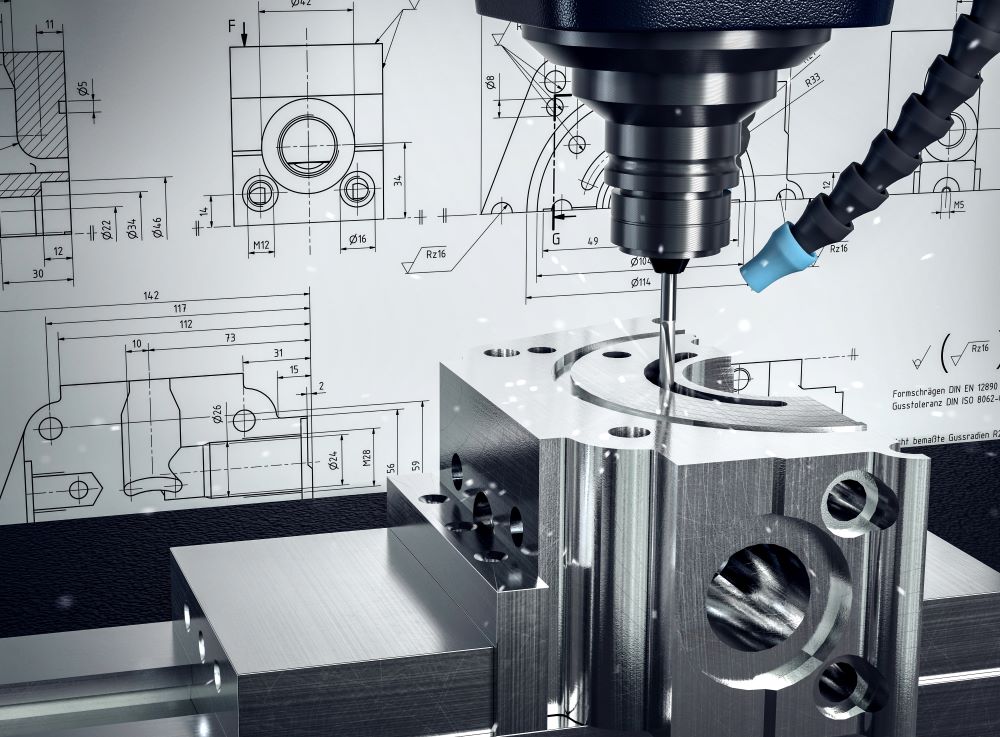

In the elaborate realm of fasteners and machining, the mission for precision and speed is a perpetual difficulty that demands precise interest to detail and tactical planning. From comprehending the diverse range of fastener types to selecting optimal products that can withstand strenuous needs, each action in the procedure plays a pivotal role in achieving the desired end result.

Understanding Bolt Kind

When picking bolts for a job, comprehending the different types available is essential for making sure ideal performance and reliability. Fasteners come in a wide variety of types, each developed for specific applications and requirements. Screws are utilized with nuts to hold materials with each other, while screws are flexible fasteners that can be used with or without a nut, relying on the application. Nuts, on the other hand, are internally threaded bolts that companion with screws or screws, offering a secure hold. Washing machines are vital for distributing the lots of the fastener and preventing damages to the material being secured. Additionally, rivets are irreversible fasteners that are ideal for applications where disassembly is not needed. Understanding the distinctions in between these fastener kinds is vital for picking the right one for the task, ensuring that the connection is solid, resilient, and reliable. By choosing the appropriate bolt kind, you can enhance the efficiency and longevity of your task - Fasteners and Machining.

Picking the Right Products

Understanding the value of picking the right materials is vital in ensuring the optimal performance and dependability of the picked bolt kinds discussed previously. When it pertains to bolts and machining applications, the material option plays an important duty in establishing the total strength, resilience, rust resistance, and compatibility with the designated atmosphere. Various materials use differing homes that can substantially influence the efficiency of the bolts.

Typical materials made use of for fasteners consist of steel, stainless steel, aluminum, brass, and titanium, each having its unique toughness and weaknesses. Steel is renowned for its high toughness and sturdiness, making it ideal for a large array of applications. Choosing the appropriate material entails considering aspects such as strength demands, ecological conditions, and spending plan constraints to make sure the wanted performance and longevity of the bolts.

Accuracy Machining Techniques

In enhancement to CNC machining, other precision methods like grinding, turning, milling, and boring play essential roles in bolt manufacturing. Grinding assists attain fine surface finishes and limited dimensional resistances, while turning is commonly made use of to develop round components with exact diameters. Milling and drilling procedures are crucial for shaping and producing openings in bolts, ensuring they meet precise requirements and feature correctly.

Enhancing Speed and Effectiveness

To optimize bolt production procedures, it is vital to improve procedures and apply effective strategies that enhance precision machining strategies. Automated systems can manage repetitive jobs with accuracy and speed, permitting workers to concentrate on more facility and value-added activities. By incorporating these techniques, suppliers can accomplish an equilibrium between speed and precision, ultimately boosting their competitive side in the bolt market.

Quality Assurance Actions

Executing strenuous quality assurance steps is crucial in making sure the integrity and consistency of fastener products in the production procedure. Quality assurance measures include different phases, beginning from the selection of raw materials to the final assessment of the ended up bolts. One fundamental aspect of quality assurance is performing comprehensive material assessments to confirm conformity with requirements. This entails assessing factors such as material resilience, strength, and make-up to ensure that the fasteners satisfy industry requirements. Furthermore, keeping an eye on the machining processes is important to support dimensional accuracy and surface area coating high quality. Using advanced technology, such as computerized assessment systems and precision measuring tools, can boost the precision and effectiveness of quality control treatments.

Normal calibration of tools and machinery is essential to preserve uniformity in production and make sure that bolts meet the necessary resistances. Implementing stringent methods for identifying and resolving non-conformities or flaws is essential in preventing substandard products from getting in the market. By establishing a detailed top quality control structure, manufacturers can maintain the online reputation of their brand and deliver fasteners that satisfy the highest possible criteria of performance and sturdiness.

Verdict

In the complex world of fasteners and machining, the mission for precision and speed is a perpetual difficulty that demands precise attention to Check Out Your URL detail and tactical preparation. When it comes to fasteners and machining applications, the material selection plays an essential function in identifying the general stamina, sturdiness, corrosion resistance, and compatibility with the intended environment. Accuracy machining entails different sophisticated techniques that guarantee the tight resistances and specs required for fasteners.In enhancement to CNC machining, various other accuracy methods like grinding, turning, milling, and drilling play essential functions in fastener production.To maximize fastener production procedures, it is crucial to enhance procedures and apply effective techniques that complement accuracy machining techniques.

Report this page